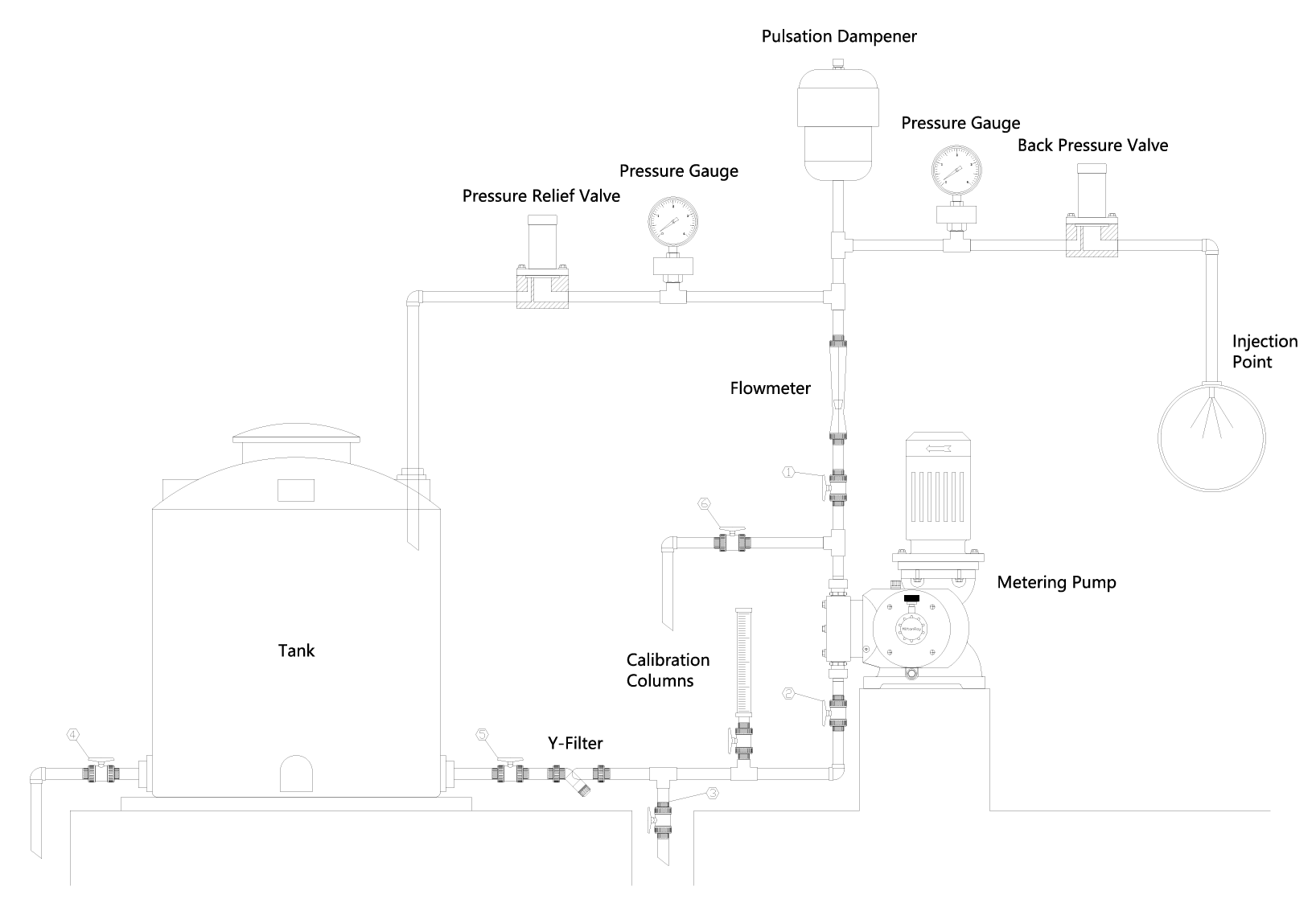

Pulsation Dampeners

Pulsation dampers are mandatory accessories for metering pumps to eliminate pulsation of the lines. Pulsation dampers smooth pulsation and water hammer caused by positive displacement pumps such as plunger pumps and diaphragm pumps. It isolates the gas from the liquid in the line by a corrosion-resistant diaphragm, smoothing the pulsation of the line through changes in the volume of the gas chamber.

1. Positive displacement pumps cause flow and pressure pulsation due to its structural and working characteristics, and adversely affect the pump and process flow. When the damper is installed in the pipeline system, the flow pressure pulsation can be effectively reduced.

2. The Pulsation Dampener shell material is UPVC、PVDF or SS316, and the diaphragm materials are FKM, NBR, and PTFE to meet the needs of different media.

Function

1. Reduce the harm of the water hammer on the system.

2. reduce the peak of the flow rate fluctuation.

3. protect the pipeline, elbow, joints from pressure fluctuations.

4. Create a good working environment for the metering pump and improve the working performance of the pump.

5. allowing the system to use smaller pipe diameters and reduce costs.

6. use with the back pressure valve can make the pressure fluctuation of the pipeline close to zero.

7. reduce the energy consumption of the system.

Operational Principle

According to Boyle’s law P1V1=P2V2, the pulsation of the pipeline is smoothed by the volume of the gas. For systems with sinusoidal curve characteristics of flow rate, when the wave peak, the volume of the air chamber becomes smaller, the Pulsation Dampener absorbs the excess flow of liquid, and during the trough, the volume of the air chamber becomes larger, and the stored liquid is released, so as to achieve the effect of smooth pulsation.

Features

It can be pre-inflated, and the effect of smooth pulsation after inflation is better than that of air-type pulsation dampers.

The gas does not come into contact with the liquid in the pipeline; the gas is not lost by dissolving into the liquid.

A limit device is provided to prevent excessive deformation of the diaphragm.

| Main Data | ||

| Model | Body Material | Volumes |

| DAP11PT | PVC | 0.1L |

| DAP21PT | PVC | 0.35L |

| DAP31PT | PVC | 0.5L |

| DAP41PT | PVC | 1.0L |

| DAP51PT | PVC | 1.5L |

| DAP61PT | PVC | 3.0L |

| DAP71PT | PVC | 5.0L |

| DAP11ST | 316L | 0.15L |

| DAP21ST | 316L | 0.2L |

| DAP31ST | 316L | 0.5L |

| DAP41ST | 316L | 1.0L |

| DAP51ST | 316L | 1.5L |

| DAP61ST | 316L | 3.0L |

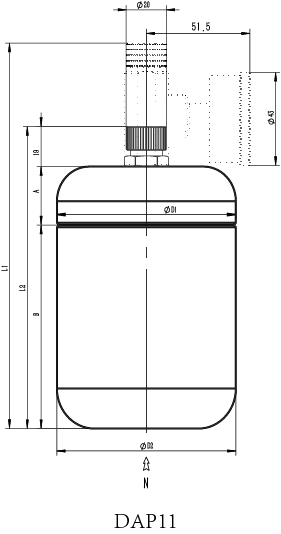

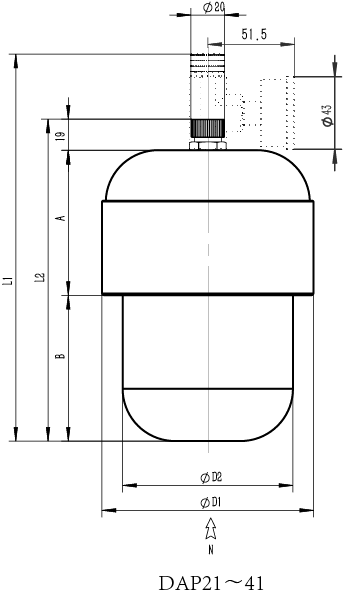

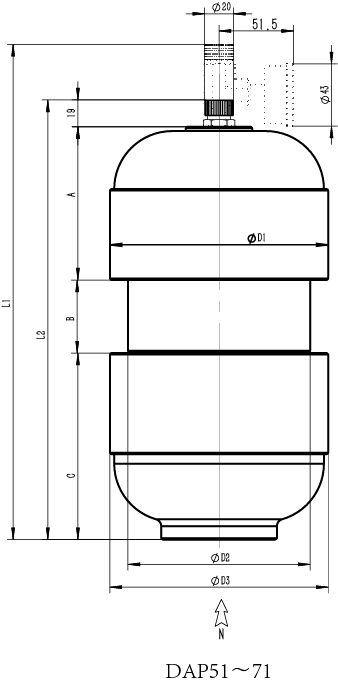

| Dimensions(mm) | ||||||||

| L1 | L2 | A | B | C | D1 | D2 | D3 | N |

| 179 | 140 | 27 | 94 | / | 90 | 90 | / | 1/2″Rc |

| 208 | 169 | 86 | 63 | / | 121 | 100 | / | 1/2″Rc |

| 231 | 192 | 86 | 88 | / | 121 | 100 | / | 1/2″Rc |

| 265 | 226 | 106 | 100 | / | 151 | 125 | / | 1″Rc |

| 344 | 305 | 106 | 50 | 130 | 151 | 125 | 151 | 1″Rc |

| 499 | 460 | 106 | 205 | 130 | 151 | 125 | 151 | 1″Rc |

| 509 | 470 | 130 | 175 | 145 | 203 | 168 | 203 | 1.5″Rc |

| 178 | 139 | 35 | 85 | / | 67 | 70 | / | 1/2″NPT |

| 200 | 161 | 42 | 100 | / | 75 | 87 | / | 1/2″NPT |

| 224 | 185 | 73 | 92 | / | 100 | 86 | / | 1/2″NPT |

| 247 | 208 | 86 | 103 | / | 126 | 110 | / | 1″NPT |

| 329 | 290 | 86 | 83 | 102 | 126 | 112 | 126 | 1″NPT |

| 495 | 456 | 86 | 249 | 102 | 126 | 112 | 126 | 1″NPT |

| Body Material | PVC, PVDF, 316L Stainless Steel (SS), additional materials may be available on request | ||||||||||

| Diaphragm | BIIR, FPM | ||||||||||

| Pressure Range | Plastic ≤10bar, Metal ≤24bar | ||||||||||

| Max Temperature | Plastic 45℃, Metal 60℃ | ||||||||||